- Home

- Heater

Heater

What you see is not just equipment, but great value!

Heat exchange equipment is divided into four categories: heaters, evaporators, coolers, and condensers. The standard for measuring the quality of a heat exchanger is high heat transfer efficiency, low fluid resistance, sufficient strength, reasonable structure, safety and reliability, material saving, low cost, easy manufacturing, installation, and maintenance.

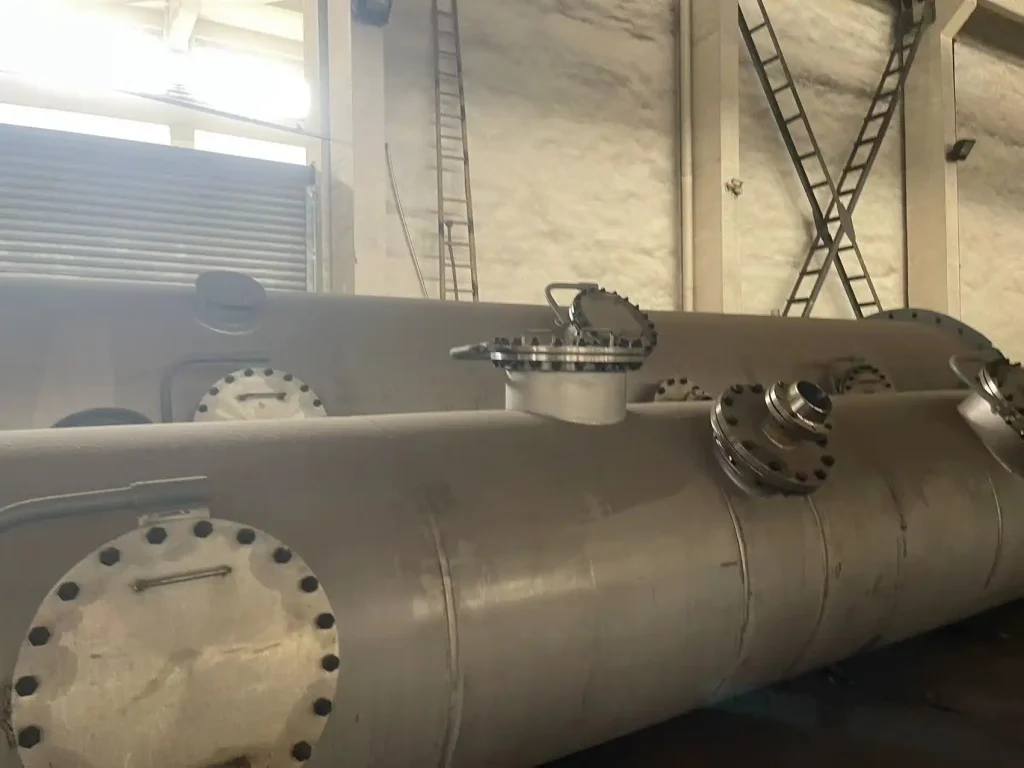

Low Pressure Heater

The main condensate water is heated by steam or steam seal leakage which. has done some work in the steam turbine to recover heat and substance. (Low pressure heater and steam seal heater are drained into condenser). With condensed water of condenser, it passes through condensate pump (injecting condensate pipe of steam seal heater and low pressure heater) and then enters deaerator.

High Pressure Heater

- Seal heater and shaft seal heater are the same equipment. Shaft seal steam is cooled, so it is called shaft seal cooler. Condensate water is heated, so it is called shaft seal heater. Shaft seal heater is also called shaft seal cooler and steam seal heater.

- Recovering steam leakage from shaft seal: air leakage from front and rear shaft seal enters the shaft seal surface heat exchanger to heat condensate water and improve thermal efficiency. The shaft seal exhaust fan pumps the steam side of the shaft seal to negative pressure, facilitating the recovery of air leakage and the discharge of hydrophobic water to the condenser.

- The shaft seal heater is usually started randomly. High-pressure steam flows out at high speed in the diffuser, forming negative pressure at the nozzle to extract excess steam seal. These vapors are then used to heat the condensate water.

- If the water level of the shaft seal heater is low, the heat transfer effect of the vacuum pump may be poor. If the initial and final pressure of the vacuum are constant, the main steam temperature will be low, leading to reduced cycle thermal efficiency.

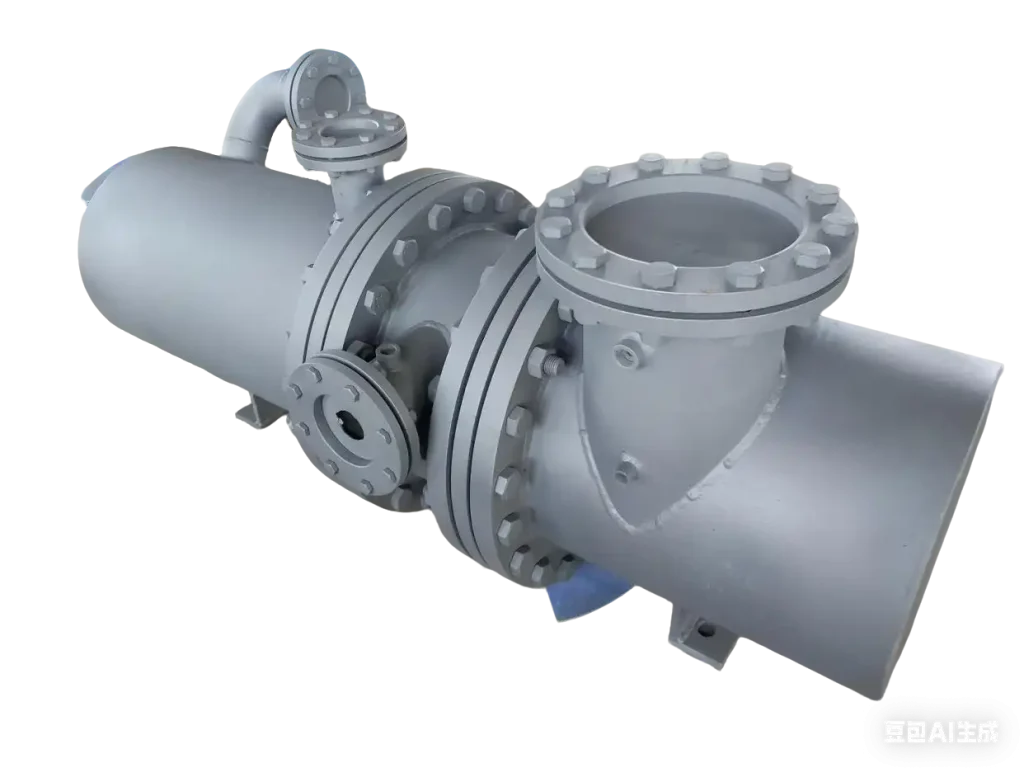

Steam /Shaft Sealh Eater

EXPLANATION OF STEAM SEAL HEATER AND SHAFT SEAL HEATER

Seal heater and shaft seal heater are the same equipment, shaft seal steam is cooled, so it is called shaft seal cooler; condensate water is heated, so it is called shaft seal heater. Shaft seal heater is also called shaft seal cooler and steam seal heater. Principle: Recovering steam leakage from shaft seal, air leakage from front and rear shaft seal enters shaft plus surface heat exchanger to heat condensate water and improve thermal efficiency. Shaft with shaft exhaust fan pumps the steam side of shaft to negative pressure for easy recovery of air leakage and generating hydrophobic water to condenser. Axis addition is usually started at random. The high-pressure Cai vapor flows out at high speed in the diffuser, forms negative pressure at the nozzle, extracts the excess steam seal, and then uses these vapors to heat the condensate water. If the water level of the shaft seal heater is low, the heat transfer effect of the vacuum pump may be poor. If the initial and final pressure of the vacuum are constant, the main temperature will be low and the cycle thermal efficiency will be low.

Oil Cooler

THE FUNCTION OF OIL COOLER

The main condensate water is heated by steam or steam seal leakage which. has done some work in the steam turbine to recover heat and substance. (Low pressure heater and steam seal heater are drained into condenser). With condensed water of condenser, it passes through condensate pump (injecting condensate pipe of steam seal heater and low pressure heater) and then enters deaerator.

Condenser

HE FUNCTION OF STEAM DOUBT

A heat exchanger that condenses steam into liquid is also called a condenser. Condenser is mainly used in steam turbine and chemical production process. When the condenser is used in the steam turbine, besides condensing the exhaust steam of the steam turbine into water for the reuse of the boiler, it can also create a vacuum far below the atmospheric pressure at the exhaust steam of the steam turbine, thus greatly improving the output power and thermal economy of the steam turbine.

A PPLICATION CHARACTERISTICS

In order to ensure that the recycled condensate water is not polluted by cooling water to meet the purity requirement of boiler feed water, surface condenser is needed in power plant steam turbine and marine steam turbine.

Hybrid condensers can be used in geothermal steam turbines when working steam does not need to be recovered.

In chemical production process, there are not onlymixed condensers, such as atmospheric condensers or water-jet condensers in vacuum evaporation system, but also surface condensers, such as condensation section in distillation column.